Polyvinyl chloride - PVC as a material for the Manufacturing of adhesive tapes

Polyvinyl chloride (PVC) is the third most-used plastic material on Earth, right after polyethylene and polypropylene. It was first synthesized in the year 1935. It is insoluble in water, oils or concentrated inorganic acids and bases.

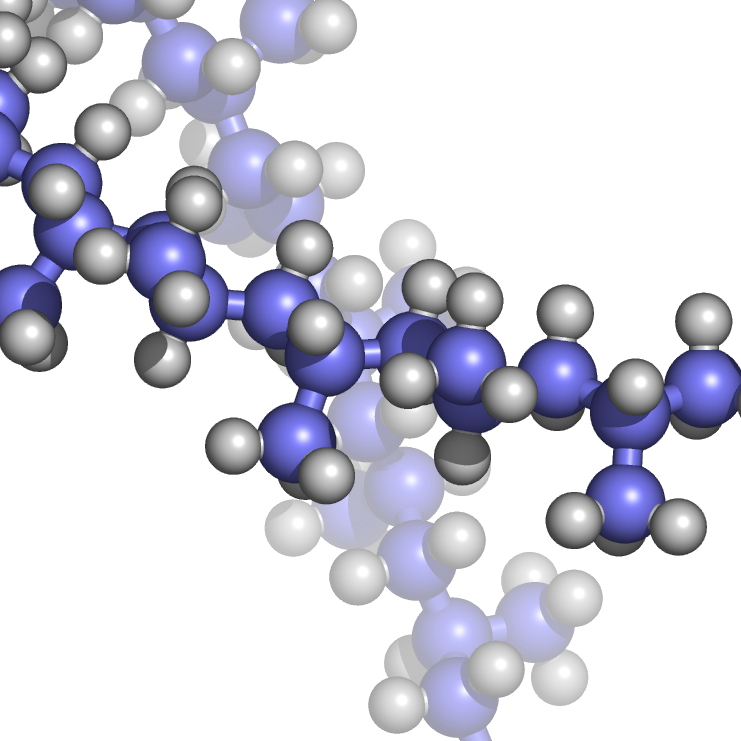

The basic component for the production of PVC is vinyl chloride monomer (VCM – a volatile, slightly sweet-smelling gas). Its polymerization into chains, only partially branched, creates a white powder or granulate. The polymer itself is then mixed with various additives, which improve its qualities in the given aspect depending on its intended use. These additives are mainly fillers (for example chalk), stabilizers (to increase thermal-stability and resistance to ultra-violet or heat radiation), softeners (for easier handling), lubricants (for easier processing) etc.

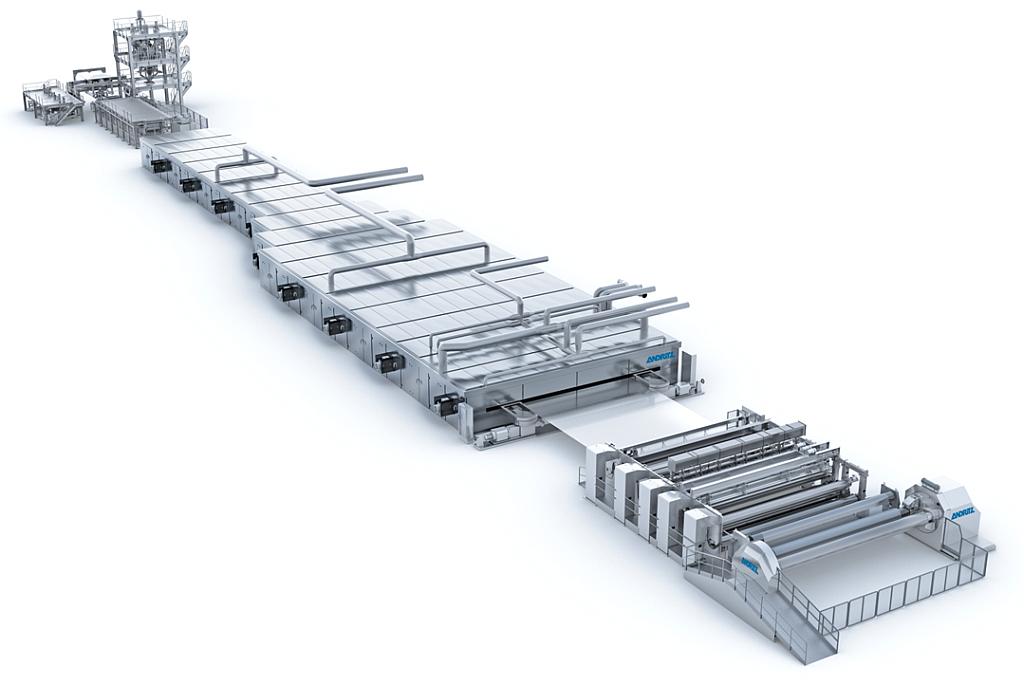

Manufacturing process of polyvinyl chloride

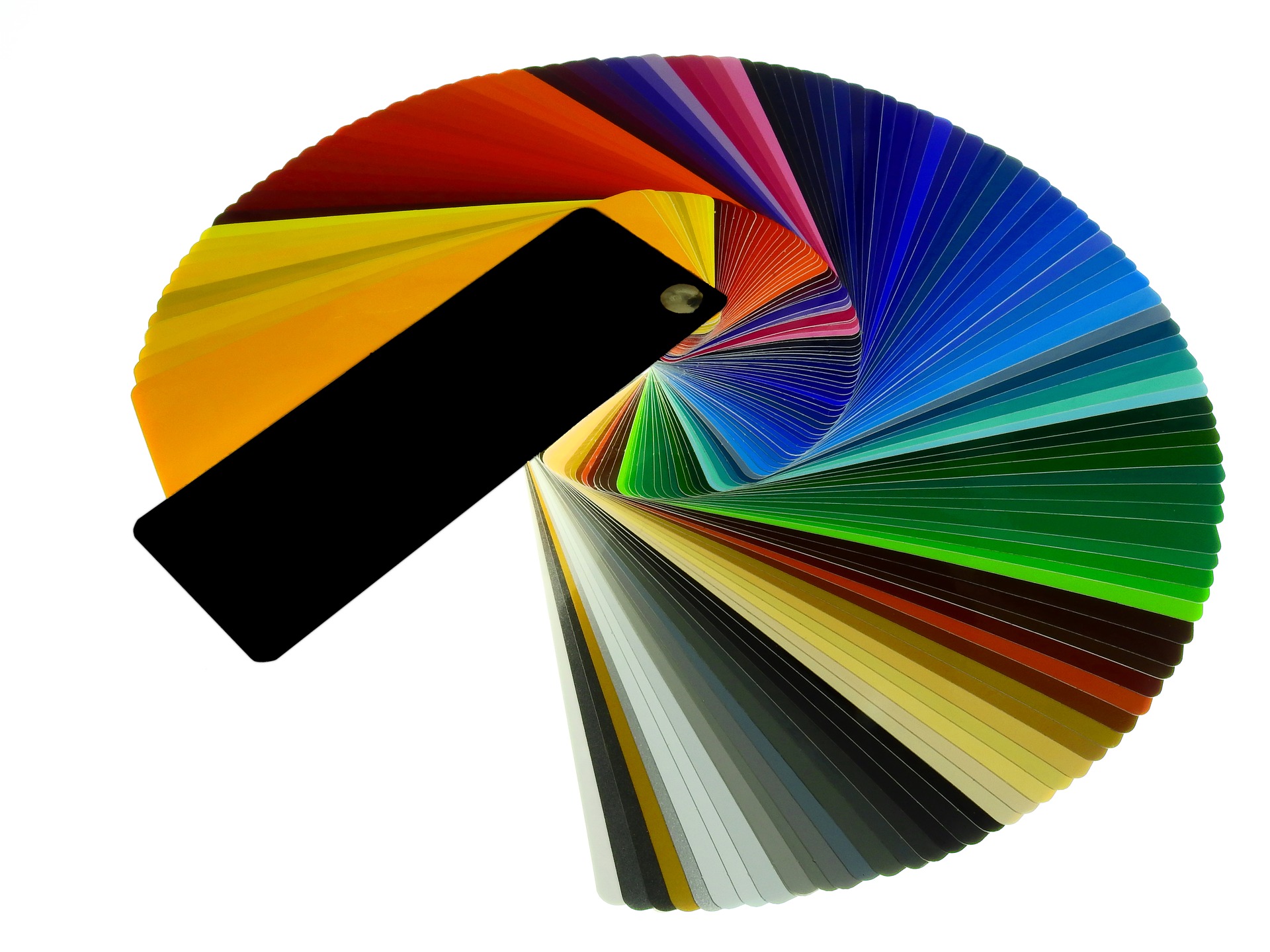

Heavy metals (cadmium, lead) or organic compounds of tin were previously also used as stabilizers, but (partly as a result of the European REACH policy), they have mostly been replaced with additives on the basis of ecological calcium. The reason for the considerably wide use of PVC is the relatively easy and thus cheap manufacturing of the basic vinyl chloride, as well as the utility properties of its polymer - easy processing by practically all of the basic methods (rolling, expression, injection, blow moulding, vacuum shaping etc.), its capacity to jellify with various softeners, considerable chemical and biological resistance to inertness, goods thermal resistance.

During production, the toxic element chlorine or the primary vinyl chloride monomer, which is carcinogenic, may leak into the environment. The manufacturing of polyvinyl chloride is accompanied by the formation of dioxins, which belong among hazardous toxic substances.

Phthalates are usually used as softeners (for example DEHP). For both adults and children without exception, phthalates endanger the functioning of kidneys and liver, they increase the risk of development of allergies or asthma.

If PVC is disposed of by incineration without a duly adjusted technology, the emissions may include undesirable side products of incineration, which are toxic, carcinogenic or otherwise hazardous substances, such as hydrogen chloride, hexachlorobenzene, polychlorinated biphenyls, furans and dioxins.

Source: Wikipedia