Flexo printing technology

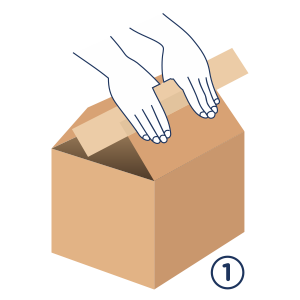

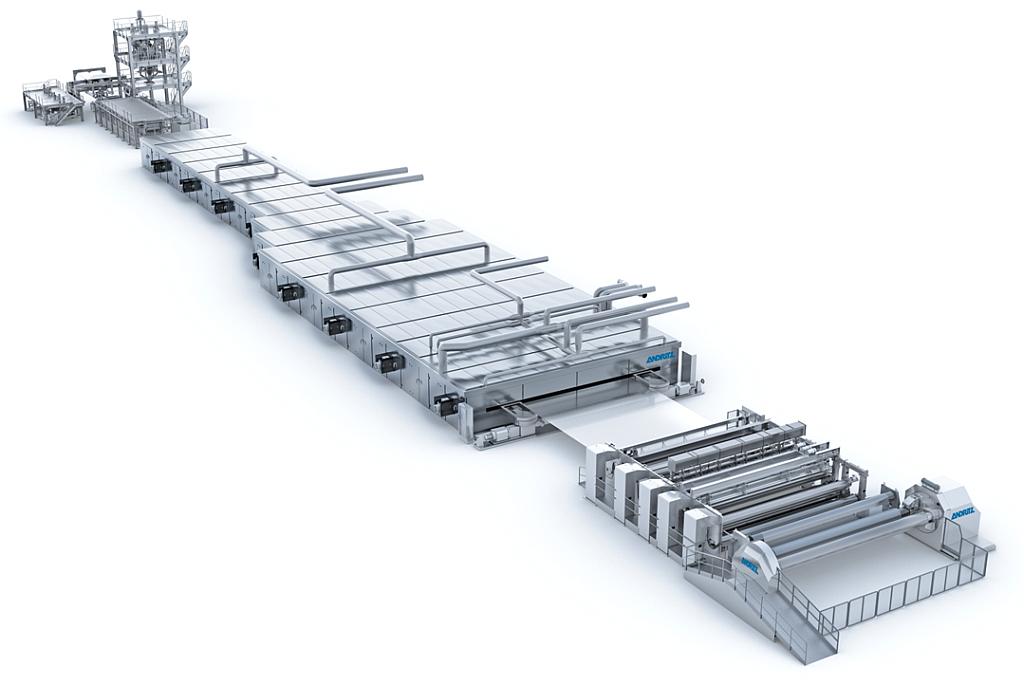

In the case of the adhesive tape printing has to be first the material basically defined. It´s printed almost exclusively with flexographic printing technology and the decisive factor is the volume of the order. For large quantities of BOPP adhesive tapes, the foil is first printed on a jumbo roll without adhesive. On the printed foil on the side of the pressure is then applied the adhesive.Therefore, this technology is also called inter-layer pressure or sandwich-pressure, because the color is between the foil and the adhesive. For smaller volumes of BOPP, for PVC or paper tapes, the material is already prefabricated (adhesive is already applied) and it´s cutted into smaller rolls.The material is then printed and cut to the final size of the tape.

These tapes are printed on the surface of the tape by using a special flexo printing machine. A surface print is used for smaller quantities up to 360 pieces, but we also have customers for whom we produce more than 8,000 pcs per year with this technology. The enormous advantage is the flexibility and the delivery time.

First we have to create the printing plates, which then transfer the ink to the foil on the printing roller. At the adhesive tape, which is printed on the surface are the colors exposed to direct exposure to the adhesive, so in some cases the imprint will not last as long as an sandwich print. Therefore, we recommend our customers to process these tapes within a certain time, about 6 months, max. one year and not to order and store for example for two years in advance. As already mentioned, the flexibility in quantity and the comparably short delivery time are of great advantage with this technology.